Individual packaging for your requirements

Individual packaging for your requirements

This folding carton was specially designed for the ELISA (enzyme-linked immunosorbent assay) test. Its partitions are precisely tailored to fit various test components in a minimal amount of space for efficiency and to protect them from breakage caused by impact, pressure or falling. The partitions prevent samples from being mixed up during transport and can be flexibly adapted to each test format using perforations.

The ELISA-KIT box’s optimal pack size helps save space and costs during transport and storage. Exceptional convenience: the boxes are easy to open and keep all test components neatly arranged and simple to remove. They are made completely of carton board, meaning they are 100% recyclable.

Our modular packaging concepts offer you improved flexibility in the packaging process. With just one pack size, you can quickly adapt and model your production processes to the life cycle of your product. These All Paper Solutions consist of 100% mono-material and are therefore completely recyclable.

The benefits for you:

- Environmentally friendly through the use of fibre-based mono-materials and environmentally friendly printing inks and varnishes

- Flexible thanks to variable and modular packaging concepts

- Customised and tailored precisely to your needs

- Efficient through economical and environmentally friendly packaging for accident-proof cartoning platforms

- Legally compliant, as Faller Packaging meets all requirements for pharmaceutical secondary packaging

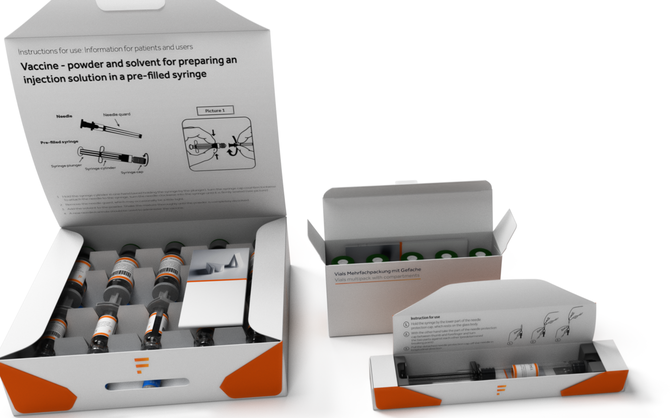

Customised complete packaging for vaccine units

Customised complete packaging for vaccine units

Intensive work on vaccines and medicines against the Covid 19 virus is in progress worldwide.

The demand for secondary packaging for such and similar drugs will increase.

Vials, ampoules or disposable syringes are often used for vaccines. We already offer customised single and multiple packaging solutions that are optimally adapted for the transport of sensitive vaccine units.

Your benefits:

- customised top-load/top-opening multi-component packaging: temperature-resistant, recyclable

- perfect machine runability and optimum packaging behaviour

- package inserts for different needs

- accommodation of all components in the smallest possible space: optimum storage, good stackability

more space for information through insinde printing - comply with legal requirements using Tamper-evident labels.

- we are a system supplier of all packaging components: folding boxes, pharmaceutical labels, package inserts

Folding cartons with a separate inner chamber

Folding cartons with a separate inner chamber

Folding cartons with a separate inner chamber can be automatically joined with another product and bonded to each other using hot glue. The integrated product is fitted perfectly to the floor element of the inner chamber. The large opening aid and perforations on the floor element make it easy to remove the integrated product and at the same time provide access to the packaging contents.

Your benefits:

- Reduction of logistical and administrative effort

- No additional investment for dispensing magazines required

- Productivity gain through the use of a more efficient packaging process with shorter setup times and fewer disruptions

- Hot glue ensures no damage to the folding carton when removing the product

- On first opening there is direct initial contact with the relevant product and usage information

Cardboard instead of plastic

Cardboard instead of plastic

Conventional packaging concepts usually include inserts made of plastic. Our alternative is an ecological packaging with inserts made of recyclable cardboard.

Faller Packaging is using resource-saving and renewable mono-material for this environmentally friendly pharmaceutical packaging. The inserts made of recyclable cardboard offer an optimal product fixation. Easy product feeding by machine and a smooth packaging process are guaranteed.

Individual Packaging Solutions

Individual Packaging Solutions

Your challenge: Having a folding carton tailored precisely to your needs.

Our solution: We use our many years of experience to design customised pharmaceutical packaging to suit your specifications. Our solutions have proved themselves in practice time and receive awards regularly.

Compact Design

Compact Design

Your challenge: Reducing costs through space-saving packaging.

Our solution: We employ precisely tailored designs to develop the perfect pack size for your secondary pharmaceutical packaging, so you can make optimal use of space during storage and transport.

Reliable Product Protection

Reliable Product Protection

Your challenge: Transport all products unbreakable.

Our solution: Optimally adapted compartments with separate chambers and height compensation for separation and clear fixing of all products in the packaging. This ensures that they are always protected against breakage, pressure and falling.

Greater Convenience

Greater Convenience

Your challenge: Ensuring a product is as convenient and comfortable to handle as possible for the user.

Our solution: Our packaging designs simplify the process of handling medication for your customers. The packaging solutions are easy to open, keep all components neatly arranged and make it easier for users to take complex medications with several components.

Plastic-free Packaging

Plastic-free Packaging

Your challenge: Using packaging material that is as sustainable as possible.

Our solution: We offer mono-material packaging solutions that are 100% recyclable.

Compliance with legal requirements: tamper evidence

Compliance with legal requirements: tamper evidence

Your challenge: The legal requirements for pharmaceutical secondary packaging have increased in recent years.

Our solution: Faller Packaging offers various closure variants to ensure first opening protection and effective product and brand protection. Our solutions include label and construction solutions for a secure tamper-evident closure as well as the printing of serialised codes on the drug package for the identification of medical devices.